info@rotarymandrels.com +91 - 98242 62250 / +91 - 99243 23998

We have perfect Measuring Equipment for the Product that perfect fr your Needs.

The material finished through these outsourced processes are supplied with authentic test certificates.

Our manufacturing processes comply with the norms of ISO 45001:2018 safety standards.

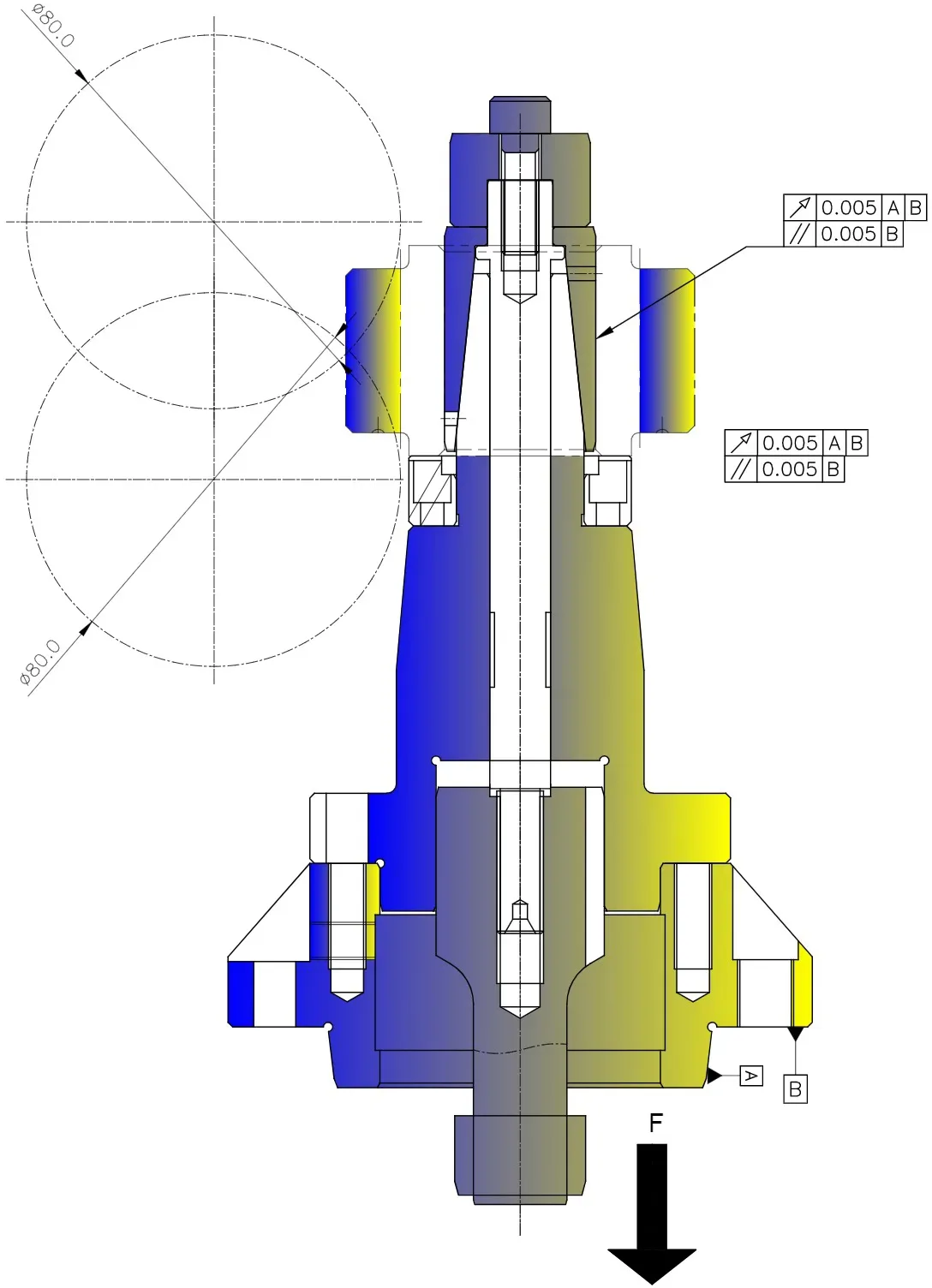

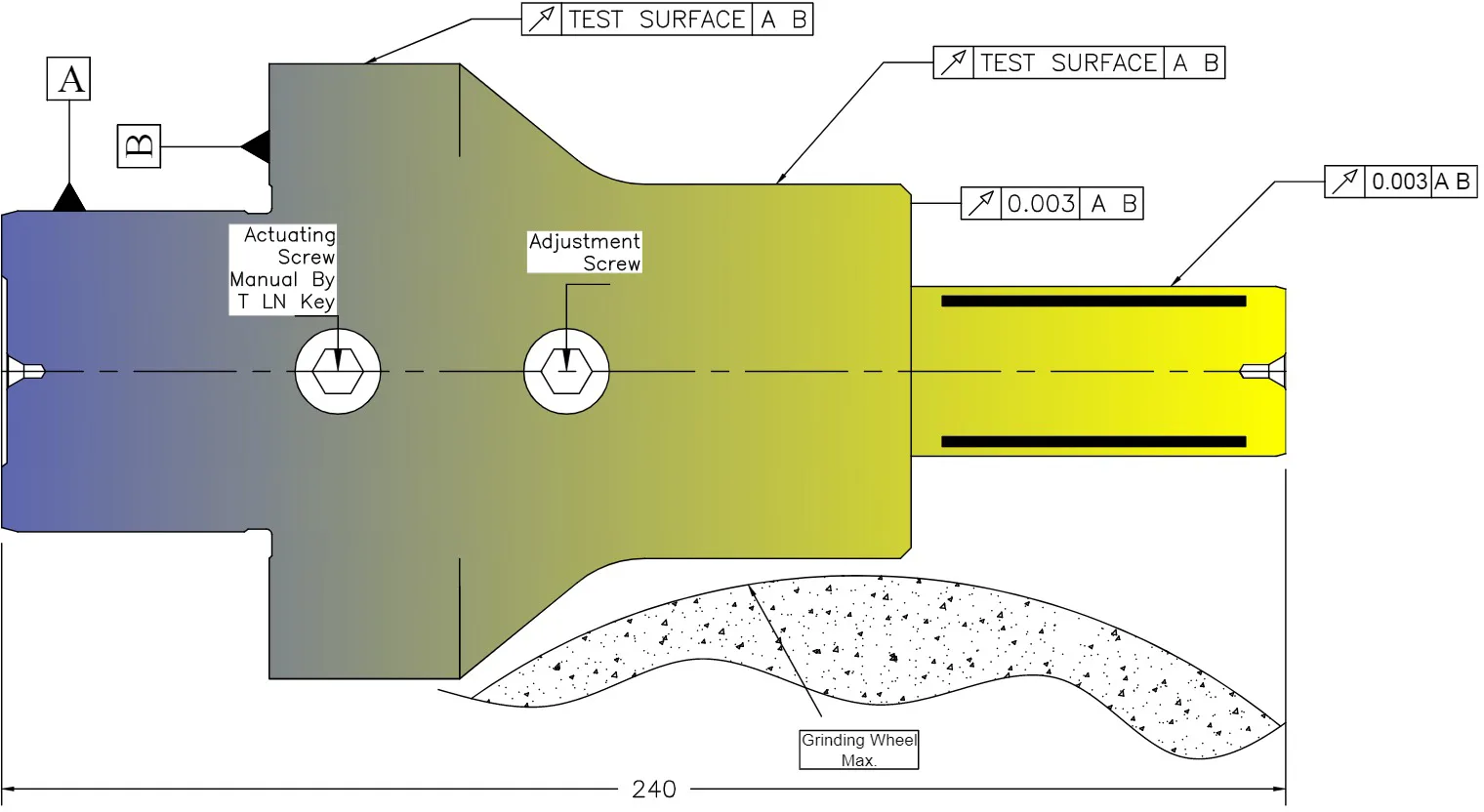

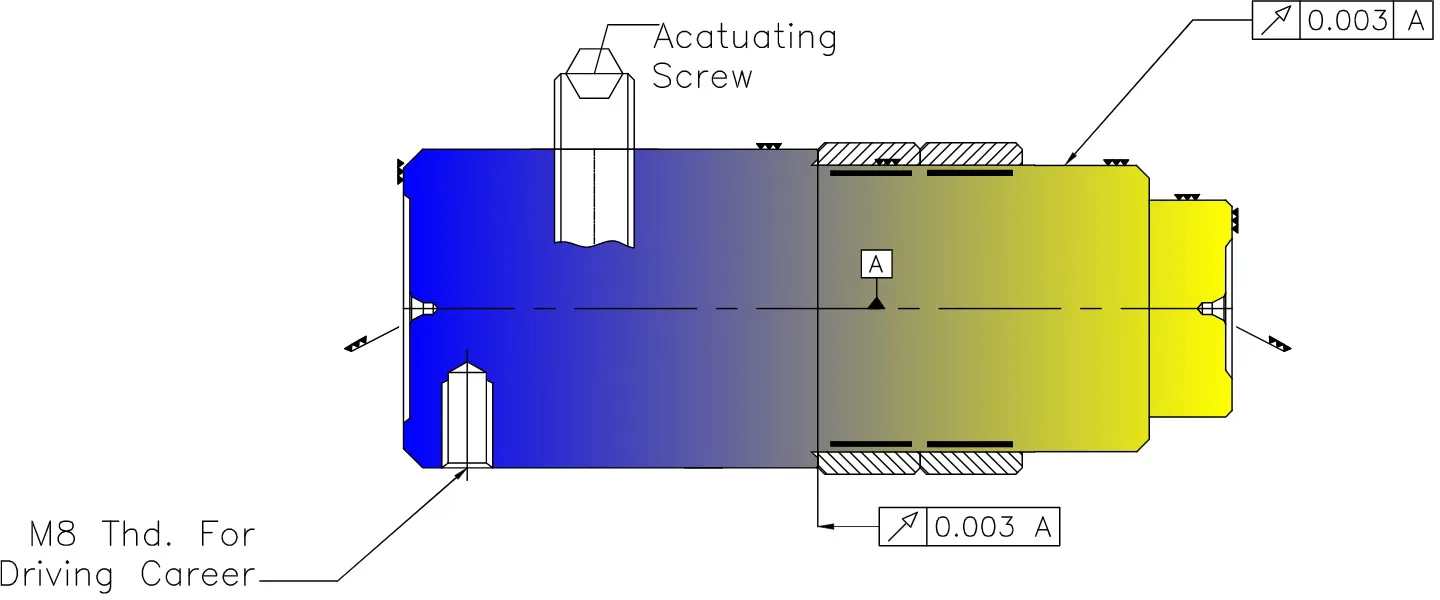

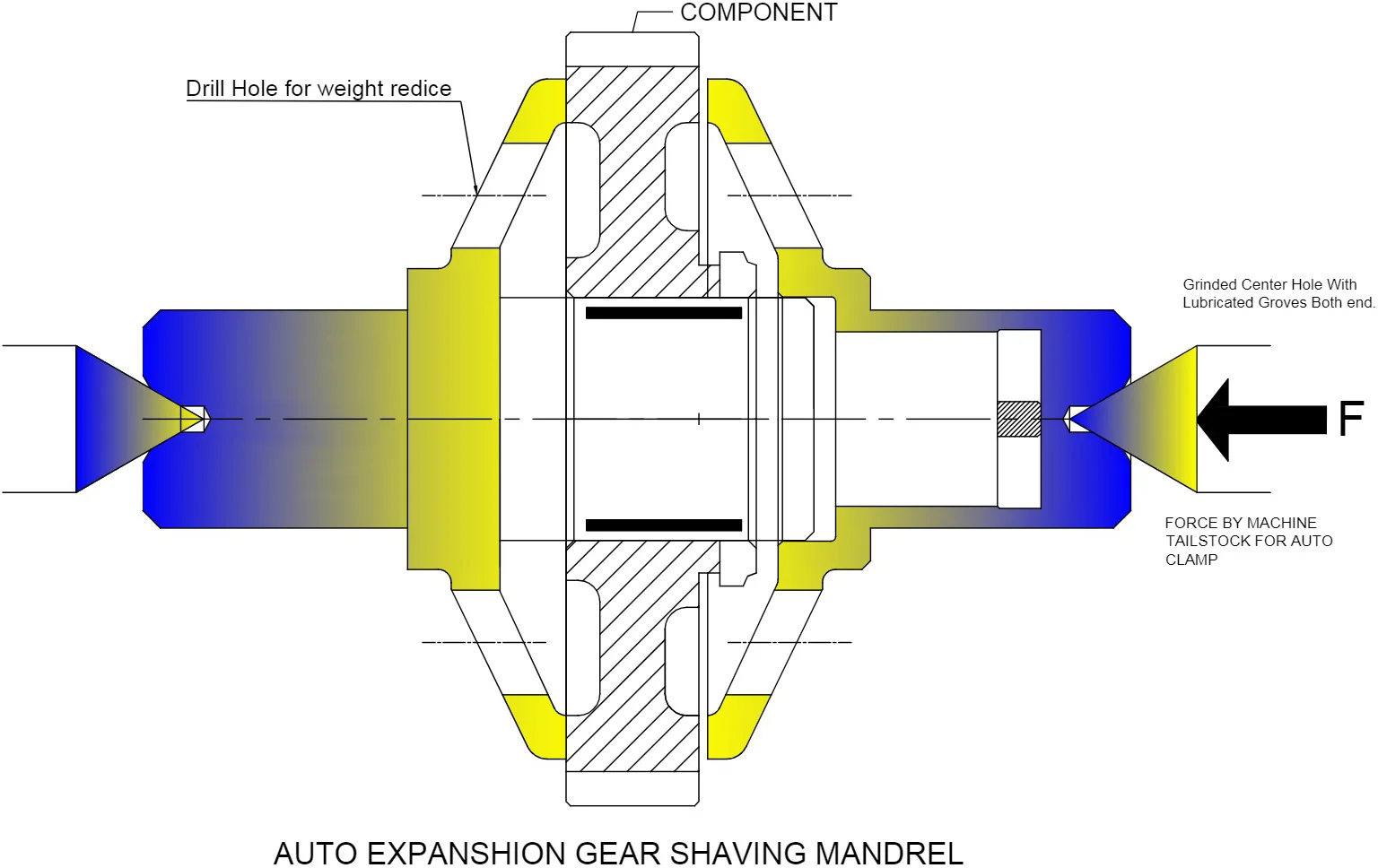

Concentric® Engineering Corporation & Rotary Engineering Corporation 1968 are manufacturer of Hydraulic Expanding Mandrel, Gear Grinding Mandrel, Clamping Solution, expandable hydraulic arbor. High precision clamping elements for modern CNC operated tooling machines. CONCENTRIC® Rotary Clamping Technology has been one of the most innovative companies in this industry for decades. The product program includes tool clamping equipment such as clamping Arbours /mandrels and chucks in hydraulic, mechanical or hydro-mechanical design, which are used in leading mechanical engineering and industrial companies under the CONCENTRIC® brand.

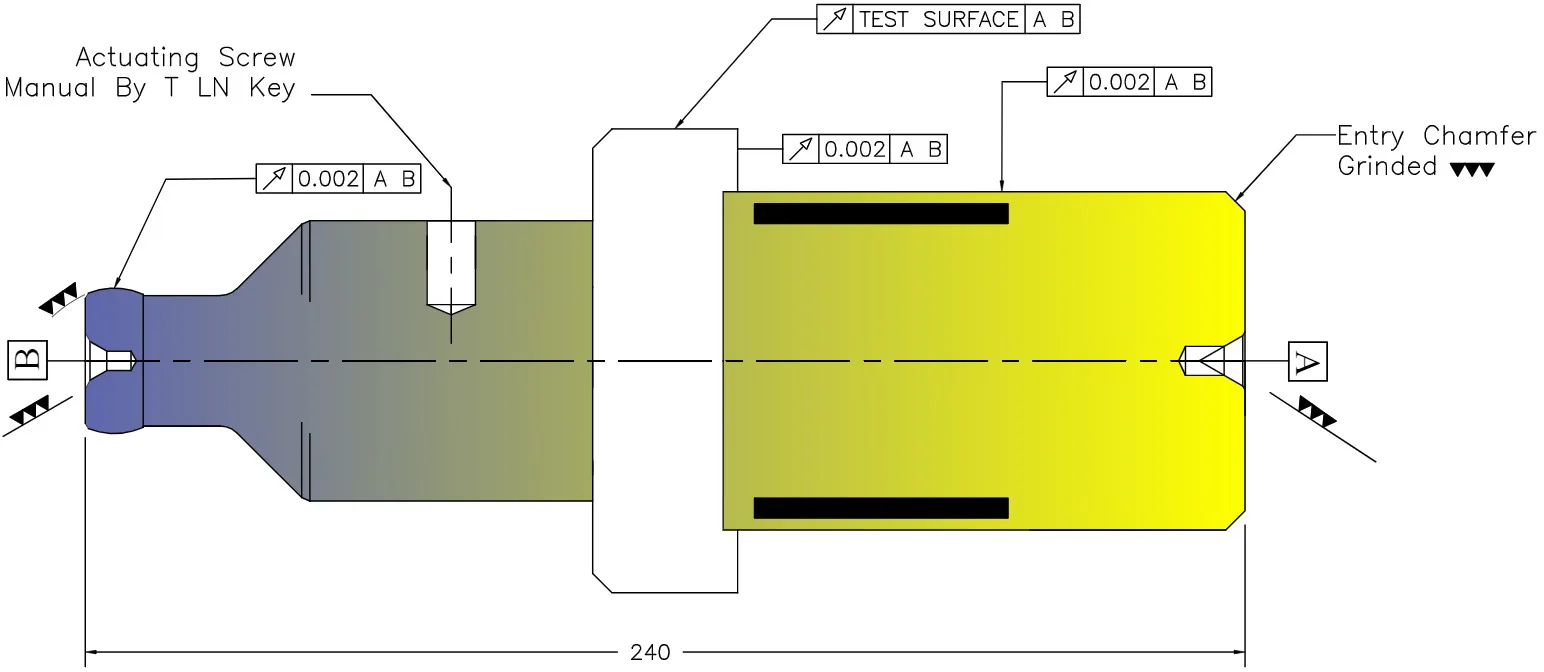

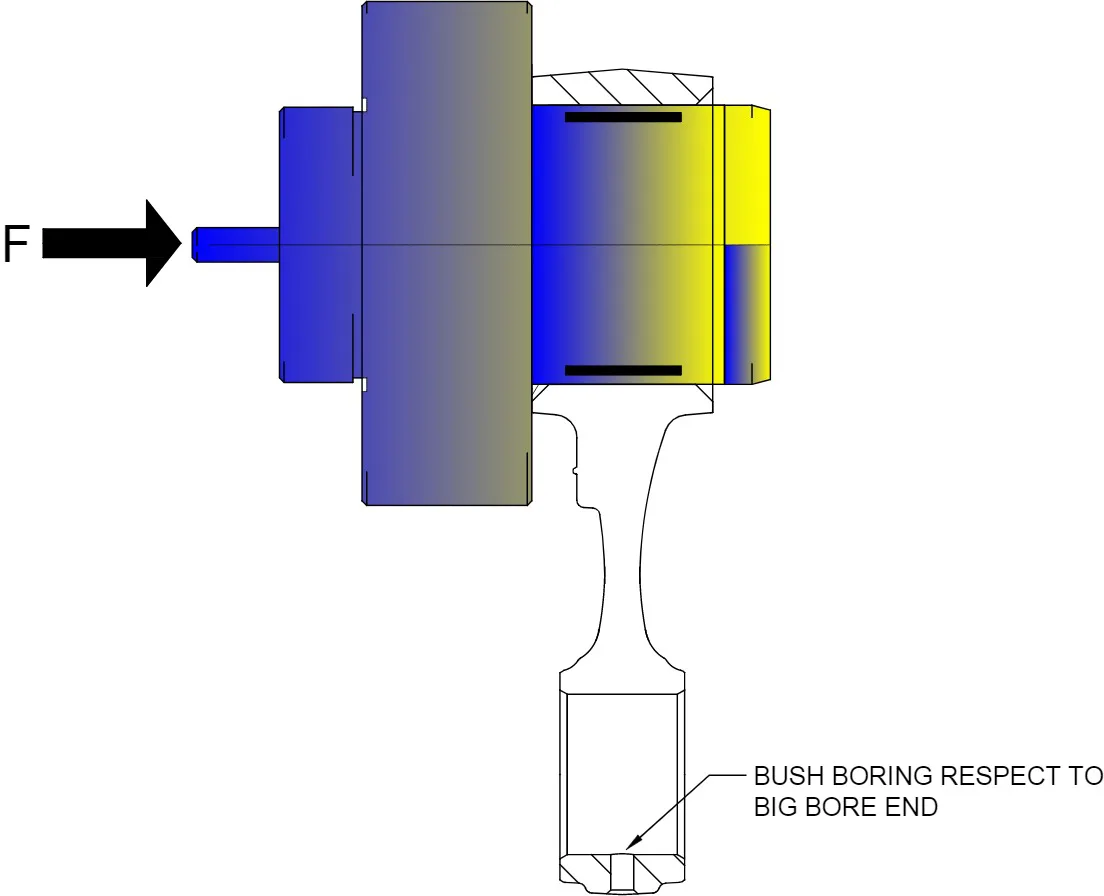

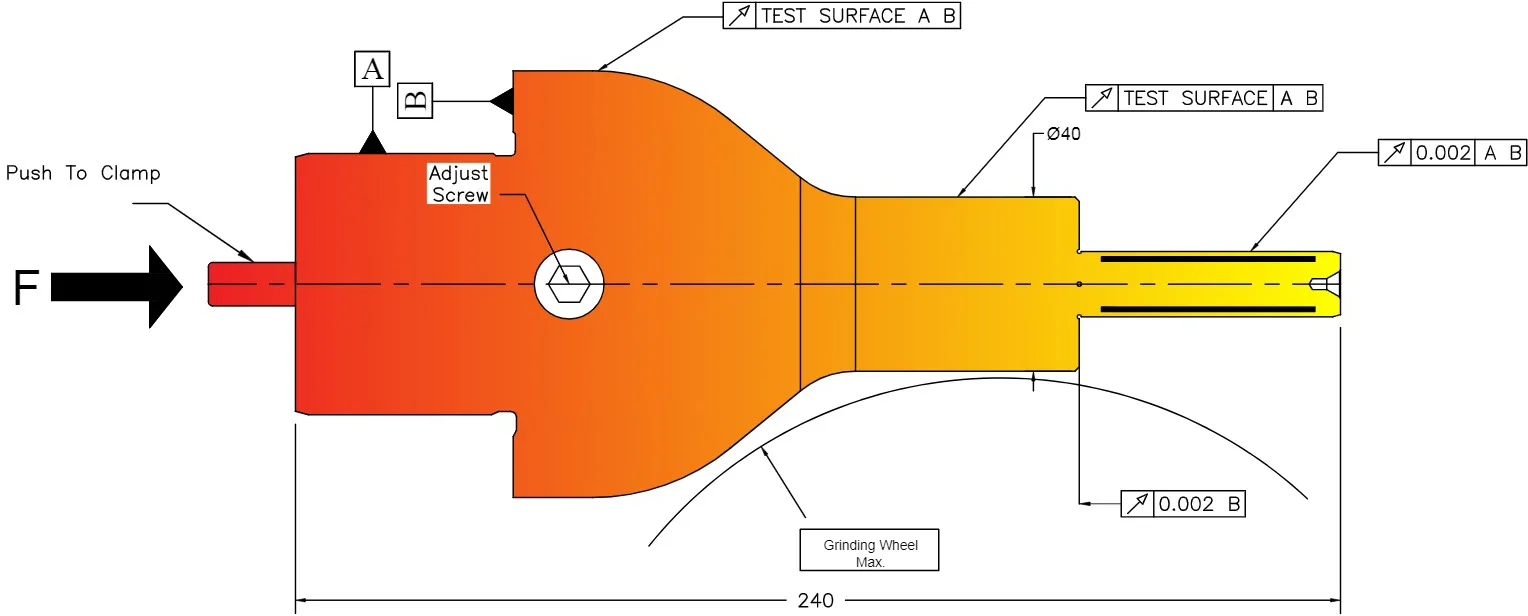

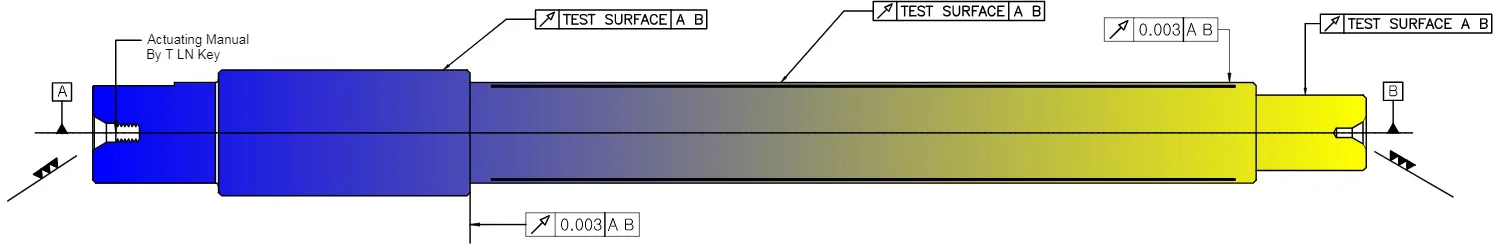

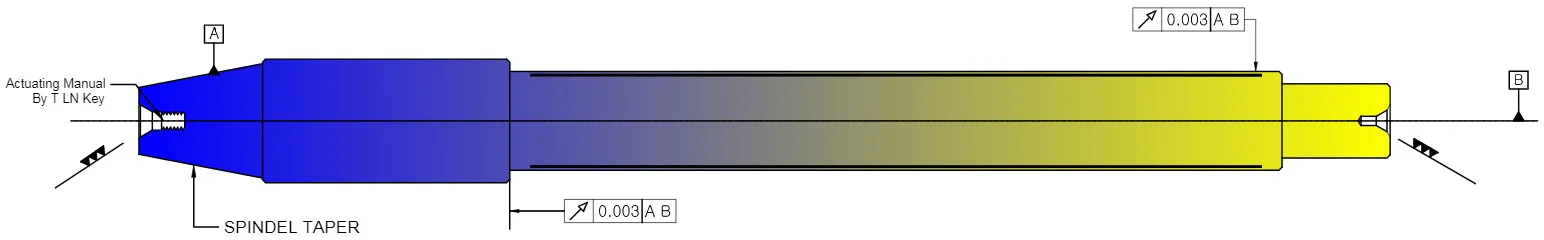

Combining in-house design and engineering capabilities with highly automated machinery and skilled manpower, our product portfolio ranges from Hydraulic Expanding Work Holding equipment such as Hydraulic Gear Grinding Mandrel / Arbour , Gear Shaving Mandrel, Thin wall OD Grinding Mandrel, Hydraulic Lock Nut , Pin Cage assembly for Gear Bore Grinding WRT Teeth PCD, Connecting Rod Bush Boring Collet and Accessories, to special profile components, Customized Tolling, Dies, Special Profile Components, Special Assembly Solutions, etc.

Continual improvement through feedback and stringent process audits (internal and external) to ensure output reliability.

Production capabilities withthe latest technology machinery to ensure quality output within tight schedules

Capable of supplying fully finished components right from raw material procurement to finished goods.

2 decades of experience in industrial engineering segment catering to Work Hollings need.

Design capability to study the feasibility analysis of customer’s drawings and standards

Strict adherence to process control through control plans and quality measurementtools

Process adherence to quality norms in manufacturing, inspection and testing methods

Systematic recordkeeping for perfect identification and traceability of products

Absolute compliance to ethical and regulatory norms

We have an experienced design and development team who have developed these products to meet your critical requirements for achieving low tolerances in the range of 3 or less microns. Apart from the standard products, we also develop customized solutions for special needs through proven design methodologies for better results.